Services

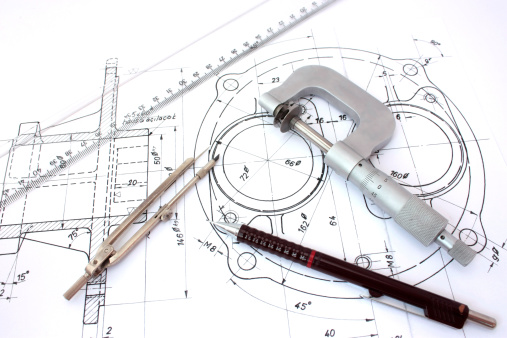

The Drawing Board

The Drawing Board

Bringing your design ideas into reality by getting them down on paper. We help in choosing best design among different ideas going through your mind for your product. In early stages of your conceptual design, these hand sketches and the logical block diagrams, help you visualize your product in greater details. Whether it’s a mechanical part/assembly, or an Electronics device idea/circuit design, talk to us, discuss different competing ideas in brainstorming sessions and we will convert your ideas in to initial feasible product/system design.

Computer Aided Design

Computer Aided Design

Based on the initial mechanical or electronics design, we create digital sketches of your idea in 2D and 3D CAD software. 2D drawings provide complete manufacturing drawings as well as PCB layout details. Whereas 3D model transforms 2D design into photorealistic prototype, helping you see approximately how a physical version of your design will look. 3D models can be rotated and animated for better visualization of your product before finalizing the design. These models can be rendered using digital textures into real life products. Multi-component mechanical assemblies and multi-layer PCBs can be created in 2D/3D CAD for better understanding and to mitigate conflicting features among different components of the assembly or circuit. Moving parts animation could help visualizing working mechanism of your conceptual product. 2D & 3D digital designs can be analyzed using Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) tools for improved performance and quality of your product. .

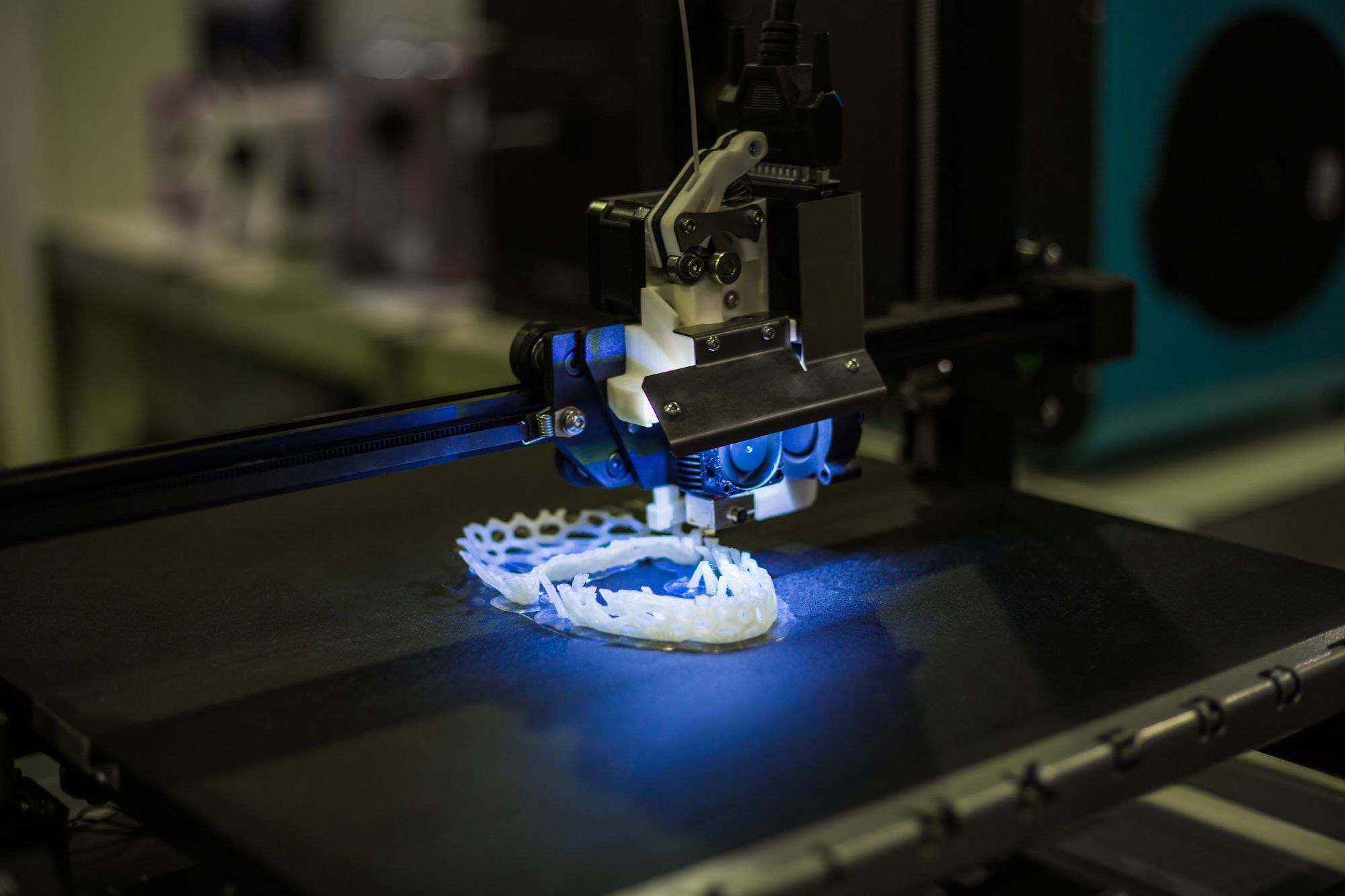

Prototype & Manufacturing

Prototype & Manufacturing

The final mechanical digital design can be converted into physical scaled model using appropriate technology. Based on the requirements of the design, the prototype could be a 3D printed product, or manufactured using conventional materials and techniques. We can convert your digital designs into tangible parts for better visualization. A complete Design for Manufacture (DFM) analysis provides detailed knowledge for converting digital designs into actual parts based on your material selection and available manufacturing techniques. We also provide cost and benefit analysis to determine time and cost to market your product. Limited quantity parts can be manufactured using conventional as well as advance manufacturing techniques. Based on your requirements, we can provide Bill of Materials as well as sources for off the shelf components/equipment needed to complete the product. We help in locating suitable manufacturer or supplier for large quantity production. The circuit schematics can be converted into physical PCB. We can source the required components, make prototype PCBs and test the assembled unit. We can facilitate with low volume production for PCBs as well as complete product. We can design and provide test and diagnostic equipment and application specific wiring harnesses. If required, the test and diagnostic equipment can be Laptop based with appropriate GUI Design.